4D Printing Market Introduction and Overview

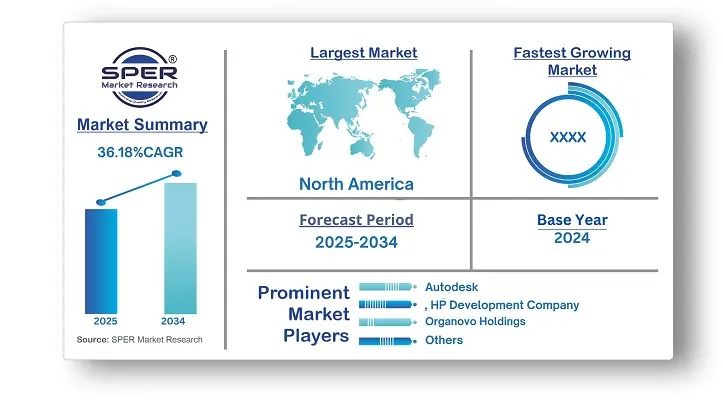

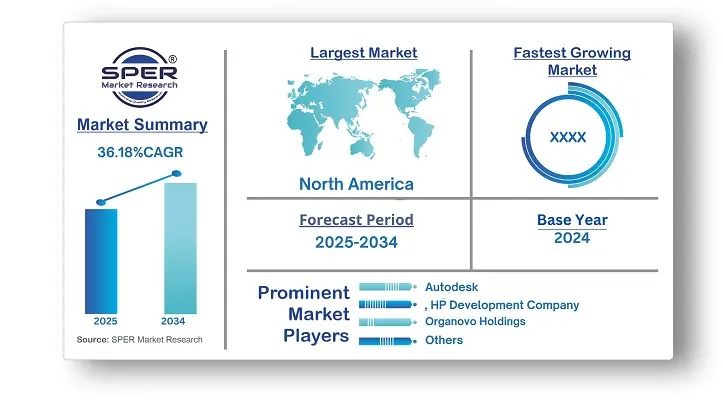

According to SPER Market Research, the Global 4D Printing Market is estimated to reach USD 4683.74 million by 2034 with a CAGR of 36.18%.

The report includes an in-depth analysis of the Global 4D Printing Market, including market size and trends, product mix, Applications, and supplier analysis. 4D printing is an innovative evolution of 3D printing that produces objects designed to change shape or function over time in response to environmental triggers like temperature, moisture, or light. It employs smart materials that can adapt and transform after being printed, enabling them to meet specific conditions or requirements. Applications of 4D printing range from self-adjusting parts in aerospace and adaptive medical implants to responsive elements in smart building structures. The 4D printing market is rapidly growing due to advancements in smart materials, such as shape-memory polymers and nanomaterials, which enable structures to adapt to environmental stimuli. Industries like aerospace, healthcare, and construction are increasingly adopting these materials for their versatility, efficiency, and sustainability. Ongoing R&D and the rise of multi-material printing continue to expand applications while reducing costs. However, high production costs, limited availability of advanced smart materials, and complex design requirements. Additionally, scalability and standardization issues hinder widespread adoption across industries.

By Material:

The programmable carbon fiber segment leads the 4D printing market due to its remarkable strength-to-weight ratio and ability to adapt to environmental changes. This makes it particularly valuable in aerospace and automotive industries, where lightweight yet durable components are essential. Its programmable nature allows for the development of highly customized, responsive structures, promoting innovation across sectors such as defense and healthcare. Industries are increasingly turning to this material for its performance-enhancing and sustainable qualities. Meanwhile, the programmable wood segment is experiencing rapid growth, driven by its eco-friendly properties and distinctive visual appeal, making it a popular choice for design-focused and sustainable applications.

By End Use:

The military and defense sector leads the 4D printing market due to its demand for advanced, adaptive materials that enhance mission performance and operational efficiency. 4D printing offers key benefits, including the creation of self-healing materials and components that adjust to changing environmental conditions. These capabilities are essential for developing innovative equipment and protective gear suited for extreme environments. The sector’s strong investment in research and development fuels the adoption of cutting-edge technologies like 4D printing. This leadership highlights the military’s commitment to leveraging innovation to strengthen defense capabilities and maintain a strategic technological advantage.

By Regional Insights

North America dominates the 4D printing market, fueled by its emphasis on technological advancements and extensive research and development initiatives. The region benefits from advanced industrial infrastructure and the active involvement of major companies and research institutions, particularly in the U.S. and Canada, across sectors like aerospace, defense, and automotive. Significant investments from both public and private sectors continue to accelerate the development and commercialization of 4D printing technologies. Meanwhile, Asia Pacific is emerging as the fastest-growing market, fueled by rapid industrialization, increasing innovation, and supportive government policies. The region's expanding tech ecosystem and global collaborations are propelling its growth.

Market Competitive Landscape

The market is moderately consolidated. Some of the market key players are Autodesk, Inc., CT CoreTechnologie Group, Dassault Systèmes, ENVISIONTEC US LLC, ExOne, HP Development Company, L.P., Materialise, Organovo Holdings, Inc., Stratasys, Others.

Recent Developments:

In June 2023, Zortrax, in collaboration with the European Space Agency (ESA), developed 4D printing technology for space applications. Utilizing the M300 Dual FDM printer and a customized version of the Z-SUITE software, they successfully 3D printed structures using shape memory polymers and electrically conductive materials.

Scope of the report:

| Report Metric | Details |

| Market size available for years | 2021-2034 |

| Base year considered | 2024 |

| Forecast period | 2025-2034 |

| Segments covered | By Material, By End Use |

| Regions covered | North America, Latin America, Asia-Pacific, Europe, and Middle East & Africa |

| Companies Covered | Autodesk, Inc., CT CoreTechnologie Group, Dassault Systèmes, ENVISIONTEC US LLC, ExOne, HP Development Company, L.P., Materialise, Organovo Holdings, Inc., Stratasys, Others |

Key Topics Covered in the Report

- Global 4D Printing Market Size (FY’2021-FY’2034)

- Overview of Global 4D Printing Market

- Segmentation of Global 4D Printing Market By Material (Programmable Carbon Fiber, Programmable Wood - Custom Printed Wood Grain, Programmable Textiles)

- Segmentation of Global 4D Printing Market By End-use (Military & Defense, Aerospace, Automotive, Healthcare, Textile, Others)

- Statistical Snap of Global 4D Printing Market

- Expansion Analysis of Global 4D Printing Market

- Problems and Obstacles in Global 4D Printing Market

- Competitive Landscape in the Global 4D Printing Market

- Details on Current Investment in Global 4D Printing Market

- Competitive Analysis of Global 4D Printing Market

- Prominent Players in the Global 4D Printing Market

- SWOT Analysis of Global 4D Printing Market

- Global 4D Printing Market Future Outlook and Projections (FY’2025-FY’2034)

- Recommendations from Analyst

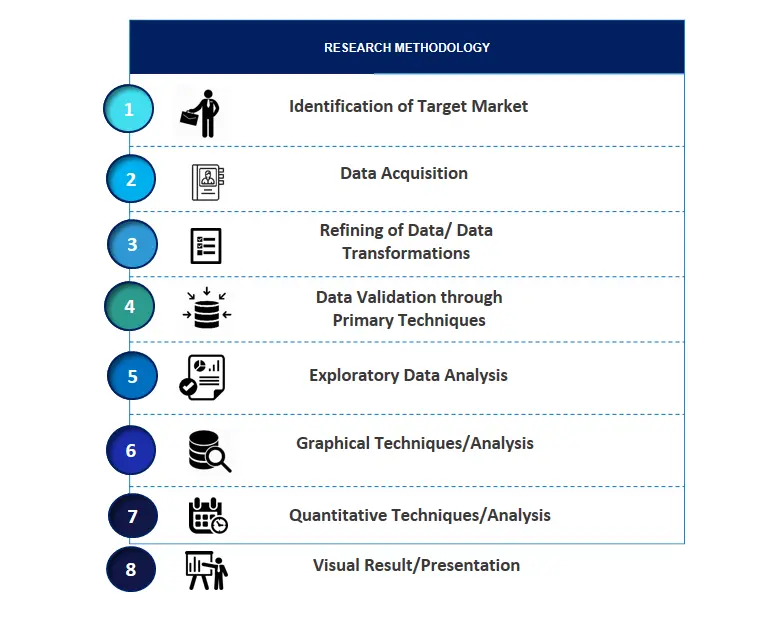

1. Introduction

1.1. Scope of the report

1.2. Market segment analysis

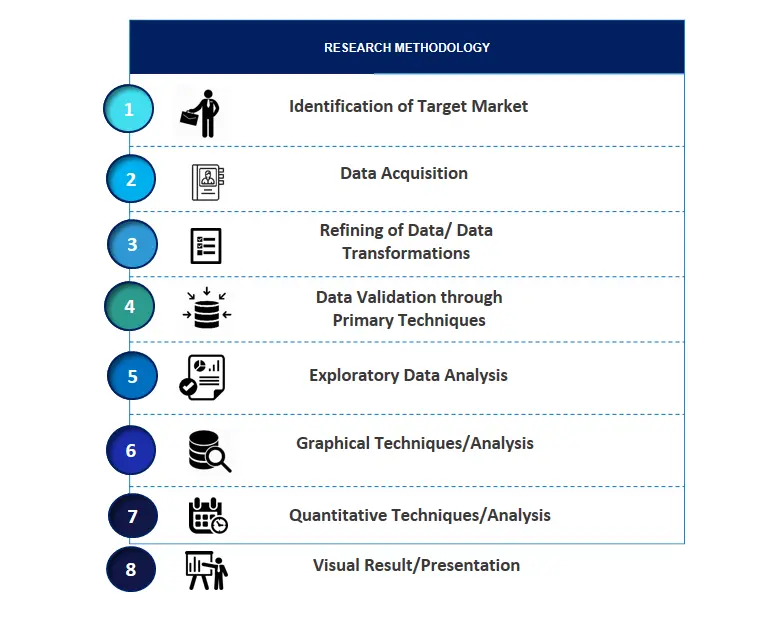

2. Research Methodology

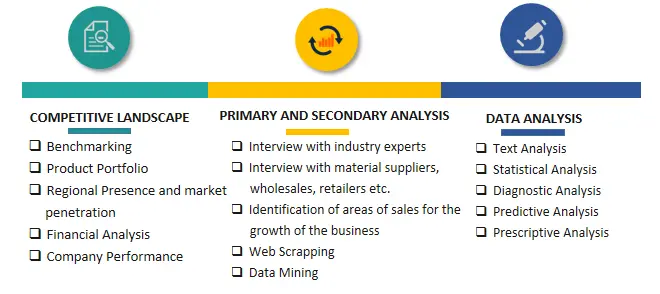

2.1. Research data source

2.1.1. Secondary Data

2.1.2. Primary Data

2.1.3. SPER’s internal database

2.1.4. Premium insight from KOL’s

2.2. Market size estimation

2.2.1. Top-down and Bottom-up approach

2.3. Data triangulation

3. Executive Summary

4. Market Dynamics

4.1. Driver, Restraint, Opportunity and Challenges analysis

4.1.1. Drivers

4.1.2. Restraints

4.1.3. Opportunities

4.1.4. Challenges

5. Market variable and outlook

5.1. SWOT Analysis

5.1.1. Strengths

5.1.2. Weaknesses

5.1.3. Opportunities

5.1.4. Threats

5.2. PESTEL Analysis

5.2.1. Political Landscape

5.2.2. Economic Landscape

5.2.3. Social Landscape

5.2.4. Technological Landscape

5.2.5. Environmental Landscape

5.2.6. Legal Landscape

5.3. PORTER’s Five Forces

5.3.1. Bargaining power of suppliers

5.3.2. Bargaining power of buyers

5.3.3. Threat of Substitute

5.3.4. Threat of new entrant

5.3.5. Competitive rivalry

5.4. Heat Map Analysis

6. Competitive Landscape

6.1. Global 4D Printing Market Manufacturing Base Distribution, Sales Area, Product Type

6.2. Mergers & Acquisitions, Partnerships, Product Launch, and Collaboration in Global 4D Printing Market

7. Global 4D Printing Market, By Material, (USD Million) 2021-2034

7.1. Programmable Carbon Fiber

7.2. Programmable Wood - Custom Printed Wood Grain

7.3. Programmable Textiles

8. Global 4D Printing Market, By End-use, (USD Million) 2021-2034

8.1. Military & Defense

8.2. Aerospace

8.3. Automotive

8.4. Healthcare

8.5. Textile

8.6. Others

9. Global 4D Printing Market, (USD Million) 2021-2034

9.1. Global 4D Printing Market Size and Market Share

10. Global 4D Printing Market, By Region, 2021-2034 (USD Million)

10.1. Asia-Pacific

10.1.1. Australia

10.1.2. China

10.1.3. India

10.1.4. Japan

10.1.5. South Korea

10.1.6. Rest of Asia-Pacific

10.2. Europe

10.2.1. France

10.2.2. Germany

10.2.3. Italy

10.2.4. Spain

10.2.5. United Kingdom

10.2.6. Rest of Europe

10.3. Middle East and Africa

10.3.1. Kingdom of Saudi Arabia

10.3.2. United Arab Emirates

10.3.3. Qatar

10.3.4. South Africa

10.3.5. Egypt

10.3.6. Morocco

10.3.7. Nigeria

10.3.8. Rest of Middle-East and Africa

10.4. North America

10.4.1. Canada

10.4.2. Mexico

10.4.3. United States

10.5. Latin America

10.5.1. Argentina

10.5.2. Brazil

10.5.3. Rest of Latin America

11. Company Profile

11.1. Autodesk, Inc.

11.1.1. Company details

11.1.2. Financial outlook

11.1.3. Product summary

11.1.4. Recent developments

11.2. CT CoreTechnologie Group

11.2.1. Company details

11.2.2. Financial outlook

11.2.3. Product summary

11.2.4. Recent developments

11.3. Dassault Systemes

11.3.1. Company details

11.3.2. Financial outlook

11.3.3. Product summary

11.3.4. Recent developments

11.4. ENVISIONTEC US LLC

11.4.1. Company details

11.4.2. Financial outlook

11.4.3. Product summary

11.4.4. Recent developments

11.5. ExOne

11.5.1. Company details

11.5.2. Financial outlook

11.5.3. Product summary

11.5.4. Recent developments

11.6. HP Development Company, L.P.

11.6.1. Company details

11.6.2. Financial outlook

11.6.3. Product summary

11.6.4. Recent developments

11.7. Materialise

11.7.1. Company details

11.7.2. Financial outlook

11.7.3. Product summary

11.7.4. Recent developments

11.8. Organovo Holdings, Inc.

11.8.1. Company details

11.8.2. Financial outlook

11.8.3. Product summary

11.8.4. Recent developments

11.9. Stratasys

11.9.1. Company details

11.9.2. Financial outlook

11.9.3. Product summary

11.9.4. Recent developments

11.10. Others

12. Conclusion

13. List of Abbreviations

14. Reference Links

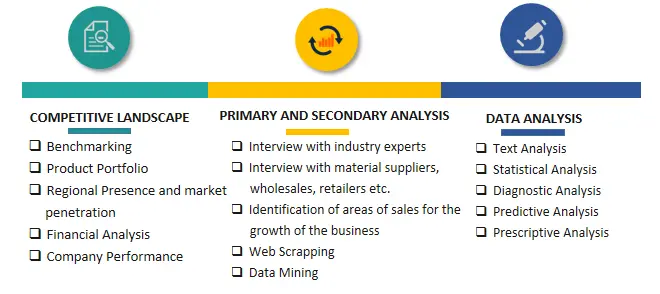

SPER Market Research’s methodology uses great emphasis on primary research to ensure that the market intelligence insights are up to date, reliable and accurate. Primary interviews are done with players involved in each phase of a supply chain to analyze the market forecasting. The secondary research method is used to help you fully understand how the future markets and the spending patterns look likes.

The report is based on in-depth qualitative and quantitative analysis of the Product Market. The quantitative analysis involves the application of various projection and sampling techniques. The qualitative analysis involves primary interviews, surveys, and vendor briefings. The data gathered as a result of these processes are validated through experts opinion. Our research methodology entails an ideal mixture of primary and secondary initiatives.