Blow Molding Resin Market Introduction and Overview

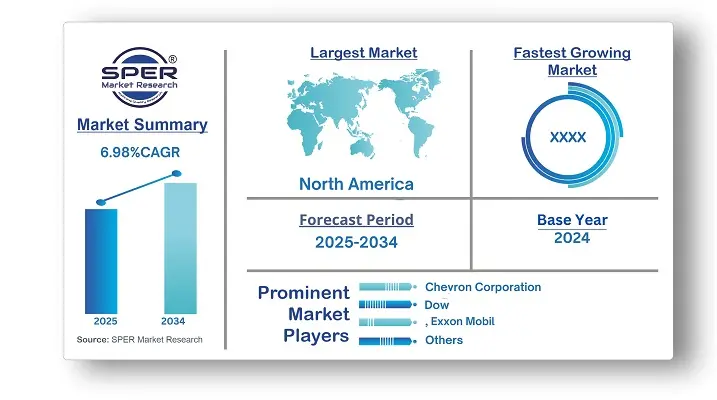

According to SPER Market Research, the Global Blow Molding Resin Market is estimated to reach USD XX billion by 2034 with a CAGR of 6.81%.

The report includes an in-depth analysis of the Global Blow Molding Resin Market, including market size and trends, product mix, Applications, and supplier analysis. The industry is seeing consistent growth, fueled by rising demand for lightweight and sustainable packaging solutions in the food & beverage, pharmaceutical, and automotive sectors. Key trends include a move toward recycled and bio-based resins, advancements in barrier technologies, and a stronger focus on circular economy principles. However, The Blow Molding Resin Market faces obstacles like fluctuating raw material prices and environmental concerns over plastic waste. Additionally, there is pressure to innovate while meeting stringent regulatory standards for sustainability.

By Resin Type:

Based on resin type, the market is categorized into polyethylene, polypropylene, polyethylene terephthalate, polyvinyl chloride, and others. Polyethylene (PE) continues to be a leading material in the blow molding resin industry, with a strong focus on innovation and sustainability. Manufacturers are working on developing high-performance PE resins with enhanced mechanical properties, such as improved strength and barrier capabilities, to meet the evolving demands of various applications. Additionally, there is increasing demand for recycled PE resins, driven by environmental concerns and regulatory requirements.

By Molding Process:

Based on the molding process, the market is categorized into extrusion, injection blow molding, blow molding and stretch blow molding. The extrusion blow molding segment is experiencing a shift toward greater efficiency and sustainability. Manufacturers are investing in advanced machinery and process improvements to boost production capabilities while minimizing energy use and material waste. Additionally, there is an increasing demand for recyclable and bio-based resins in extrusion blow molding, driven by environmental concerns and regulatory pressures, steering the market toward more eco-friendly solutions.

By End User:

Based on end-use, the market is segmented into automotive, pharmaceuticals, food & beverages, cosmetics & personal care, chemicals, and others. In the automotive sector, the blow molding resin market is seeing a shift toward lightweighting and sustainability. Manufacturers are increasingly using blow-molded components made from resins like polyethylene and polypropylene to reduce vehicle weight and enhance fuel efficiency.

By Regional Insights

Asia Pacific led the global blow molding resin industry in 2023 and is projected to continue growing at a strong rate throughout the forecast period. In this region, the market is experiencing substantial growth driven by expanding manufacturing sectors and increasing consumer demand for packaged goods. Key trends include the widespread adoption of advanced blow molding technologies, such as injection blow molding, to efficiently meet rising production needs. Additionally, there is a shift toward sustainable materials, with an emphasis on recycled and bio-based resins, reflecting the region's commitment to environmental conservation and spurring innovation in the market.

Market Competitive Landscape

The market is moderately consolidated. Some of the market key players are Chevron Corporation, Dow, Eastman Chemical Company, Exxon Mobil, INEOS, Lanxess, SABIC, Solvay, Toray Industries, and others.

Recent Developments:

In 2023, Toray Industries, Inc. announced an expansion of its high-performance chemical-recycled polybutylene terephthalate (PBT) resin product range. The company depolymerizes waste PBT from manufacturing processes and repolymerizes it. The newly introduced products include glass-fiber-reinforced grades that offer low warpage and enhanced hydrolysis resistance.

Scope of the report:

| Report Metric | Details |

| Market size available for years | 2021-2034 |

| Base year considered | 2024 |

| Forecast period | 2025-2034 |

| Segments covered | By Resin, By Molding Process, By End Use |

| Regions covered | North America, Latin America, Asia-Pacific, Europe, and Middle East & Africa |

| Companies Covered | Chevron Corporation, Dow, Eastman Chemical Company, Exxon Mobil, INEOS, Lanxess, SABIC, Solvay, Toray Industries, and others..

|

Key Topics Covered in the Report

- Global Blow Molding Resin Market Size (FY’2021-FY’2034)

- Overview of Global Blow Molding Resin Market

- Segmentation of Global Blow Molding Resin Market By Resin Type (Polyethylene, Polypropylene, Polyethylene Terephthalate, Polyvinyl Chloride, Others)

- Segmentation of Global Blow Molding Resin Market By Molding Process (Extrusion Blow Molding, Injection Blow Molding, Stretch Blow Molding)

- Segmentation of Global Blow Molding Resin Market By End-use (Automotive, Pharmaceutical, Food & Beverage, Cosmetics & Personal Care, Chemical, Others)

- Statistical Snap of Global Blow Molding Resin Market

- Expansion Analysis of Global Blow Molding Resin Market

- Problems and Obstacles in Global Blow Molding Resin Market

- Competitive Landscape in the Global Blow Molding Resin Market

- Details on Current Investment in Global Blow Molding Resin Market

- Competitive Analysis of Global Blow Molding Resin Market

- Prominent Players in the Global Blow Molding Resin Market

- SWOT Analysis of Global Blow Molding Resin Market

- Global Blow Molding Resin Market Future Outlook and Projections (FY’2025-FY’2034)

- Recommendations from Analyst

1. Introduction

1.1. Scope of the report

1.2. Market segment analysis

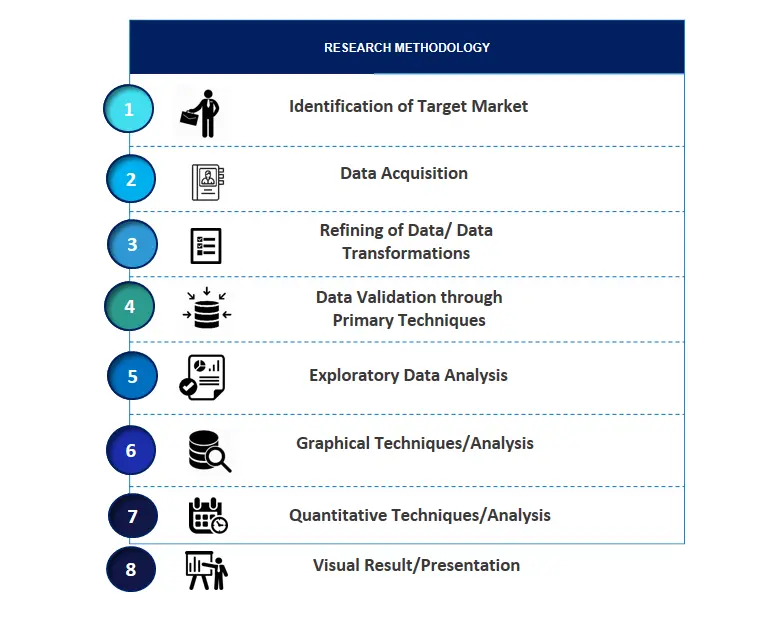

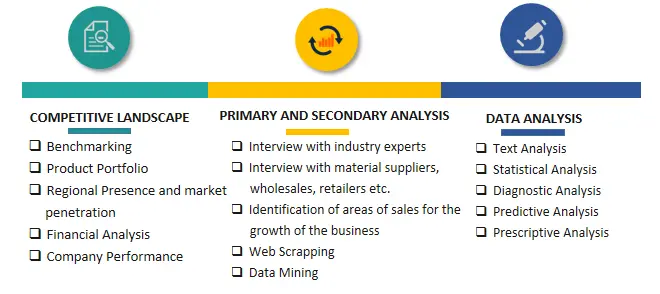

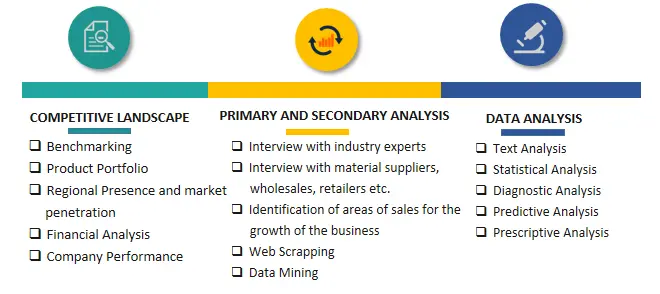

2. Research Methodology

2.1. Research data source

2.1.1. Secondary Data

2.1.2. Primary Data

2.1.3. SPER’s internal database

2.1.4. Premium insight from KOL’s

2.2. Market size estimation

2.2.1. Top-down and Bottom-up approach

2.3. Data triangulation

3. Executive Summary

4. Market Dynamics

4.1. Driver, Restraint, Opportunity and Challenges analysis

4.1.1. Drivers

4.1.2. Restraints

4.1.3. Opportunities

4.1.4. Challenges

5. Market variable and outlook

5.1. SWOT Analysis

5.1.1. Strengths

5.1.2. Weaknesses

5.1.3. Opportunities

5.1.4. Threats

5.2. PESTEL Analysis

5.2.1. Political Landscape

5.2.2. Economic Landscape

5.2.3. Social Landscape

5.2.4. Technological Landscape

5.2.5. Environmental Landscape

5.2.6. Legal Landscape

5.3. PORTER’s Five Forces

5.3.1. Bargaining power of suppliers

5.3.2. Bargaining power of buyers

5.3.3. Threat of Substitute

5.3.4. Threat of new entrant

5.3.5. Competitive rivalry

5.4. Heat Map Analysis

6. Competitive Landscape

6.1. Global Blow Molding Resin Market Manufacturing Base Distribution, Sales Area, Product Type

6.2. Mergers & Acquisitions, Partnerships, Product Launch, and Collaboration in Global Blow Molding Resin Market

7. Global Blow Molding Resin Market, By Resin Type, (USD Million) 2021-2034

7.1. Polyethylene

7.2. Polypropylene

7.3. Polyethylene Terephthalate

7.4. Polyvinyl Chloride

7.5. Others

8. Global Blow Molding Resin Market, By Molding Process, (USD Million) 2021-2034

8.1. Extrusion Blow Molding

8.2. Injection Blow Molding

8.3. Stretch Blow Molding

9. Global Blow Molding Resin Market, By End-use, (USD Million) 2021-2034

9.1. Automotive

9.2. Pharmaceutical

9.3. Food & Beverage

9.4. Cosmetics & Personal Care

9.5. Chemical

9.6. Others

10. Global Blow Molding Resin Market, (USD Million) 2021-2034

10.1. Global Blow Molding Resin Market Size and Market Share

11. Global Blow Molding Resin Market, By Region, 2021-2034 (USD Million)

11.1. Asia-Pacific

11.1.1. Australia

11.1.2. China

11.1.3. India

11.1.4. Japan

11.1.5. South Korea

11.1.6. Rest of Asia-Pacific

11.2. Europe

11.2.1. France

11.2.2. Germany

11.2.3. Italy

11.2.4. Spain

11.2.5. United Kingdom

11.2.6. Rest of Europe

11.3. Middle East and Africa

11.3.1. Kingdom of Saudi Arabia

11.3.2. United Arab Emirates

11.3.3. Qatar

11.3.4. South Africa

11.3.5. Egypt

11.3.6. Morocco

11.3.7. Nigeria

11.3.8. Rest of Middle-East and Africa

11.4. North America

11.4.1. Canada

11.4.2. Mexico

11.4.3. United States

11.5. Latin America

11.5.1. Argentina

11.5.2. Brazil

11.5.3. Rest of Latin America

12. Company Profile

12.1. Chevron Corporation

12.1.1. Company details

12.1.2. Financial outlook

12.1.3. Product summary

12.1.4. Recent developments

12.2. Dow

12.2.1. Company details

12.2.2. Financial outlook

12.2.3. Product summary

12.2.4. Recent developments

12.3. Eastman Chemical Company

12.3.1. Company details

12.3.2. Financial outlook

12.3.3. Product summary

12.3.4. Recent developments

12.4. Exxon Mobil

12.4.1. Company details

12.4.2. Financial outlook

12.4.3. Product summary

12.4.4. Recent developments

12.5. INEOS

12.5.1. Company details

12.5.2. Financial outlook

12.5.3. Product summary

12.5.4. Recent developments

12.6. Lanxess

12.6.1. Company details

12.6.2. Financial outlook

12.6.3. Product summary

12.6.4. Recent developments

12.7. SABIC

12.7.1. Company details

12.7.2. Financial outlook

12.7.3. Product summary

12.7.4. Recent developments

12.8. Solvay

12.8.1. Company details

12.8.2. Financial outlook

12.8.3. Product summary

12.8.4. Recent developments

12.9. Toray Industries

12.9.1. Company details

12.9.2. Financial outlook

12.9.3. Product summary

12.9.4. Recent developments

12.10. Others

13. Conclusion

14. List of Abbreviations

15. Reference Links

SPER Market Research’s methodology uses great emphasis on primary research to ensure that the market intelligence insights are up to date, reliable and accurate. Primary interviews are done with players involved in each phase of a supply chain to analyze the market forecasting. The secondary research method is used to help you fully understand how the future markets and the spending patterns look likes.

The report is based on in-depth qualitative and quantitative analysis of the Product Market. The quantitative analysis involves the application of various projection and sampling techniques. The qualitative analysis involves primary interviews, surveys, and vendor briefings. The data gathered as a result of these processes are validated through experts opinion. Our research methodology entails an ideal mixture of primary and secondary initiatives.